In healthcare, innovation is not just a buzzword; it's the lifeline of progress. One such groundbreaking innovation reshaping the landscape of medical treatment is point-of-care medical 3D printing. This cutting-edge technology is revolutionizing how medical devices are manufactured and transforming patient care at its core. At the forefront of this transformative technology, the University Hospital Basel is pioneering new frontiers in patient care, leveraging virtual surgical planning (VSP) and three-dimensional (3D) printing to revolutionize surgical processes, personalized treatment, and implant development [1].

Layer-by-layer additive manufacturing, or 3D printing, builds objects by adding materials one layer at a time. Unlike traditional manufacturing methods, which often involve cutting away from a larger block of material or molding, this approach allows the fabrication of more complex designs and significantly reduces material waste. The process begins with a digital 3D model sliced by the printer's software into thin, horizontal cross-sections. These slices are then printed on top of the other to form the final object [1].

Developed in the early 1980s by Charles (Chuck) Hull, who invented "stereolithography," 3D printing initially focused on industrial prototyping. Today, 3D printing is highly valued for its precision, customization capabilities, and sustainability benefits. The technology has evolved to encompass a variety of printing techniques and materials, ranging from common plastics, to advanced high-performance polymers and metals to more experimental bioinks and biomaterials for living tissues. As a result, it is now utilized across numerous industries, including medicine and surgery [1].Consider a scenario where surgeons can hold a lifelike representation of a patient's anatomy, highly detailed and tailored to their specific needs. Or envision a future in which a surgeon can precisely construct personalized implants that match a patient's specific anatomy, all within the confines of the operating room. This isn't just an unrealistic dream; at the University Hospital Basel, point-of-care medical 3D printing is making it a reality (Figure 1).

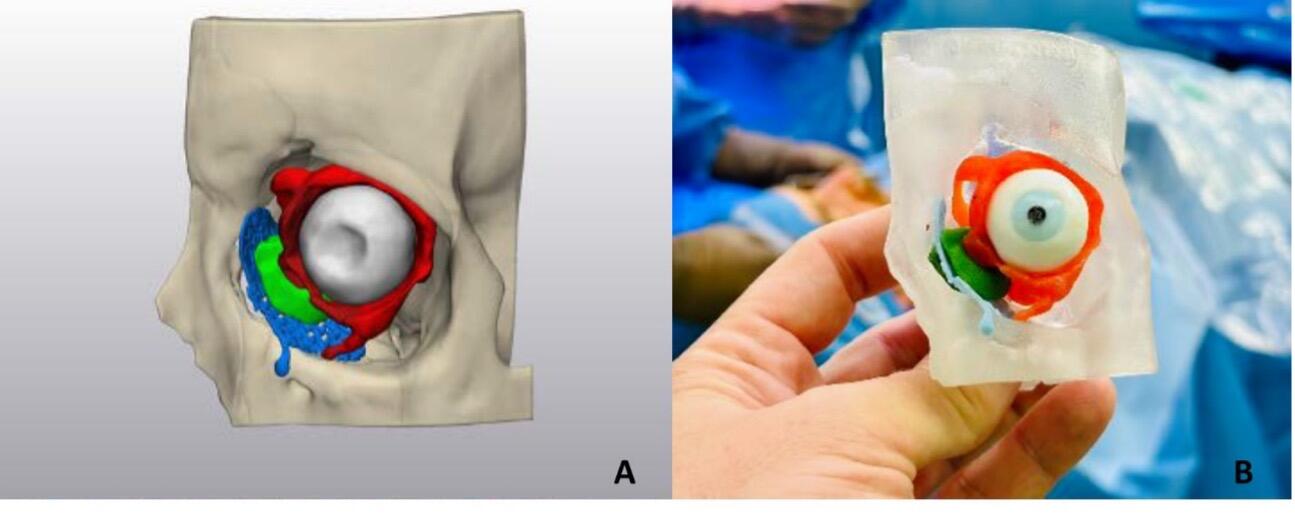

Anatomical models developed from patients' image data sets, such as computed tomography (CT) and magnetic resonance imaging (MRI), are of immense value when planning an operation, medical education, surgical skills training and patient consultation [2,3]. These 3D-printed models, in turn, allow surgeons to gain a concrete understanding of complex anatomical structures, helping to visualize procedures and devise optimal surgical plans with unprecedented accuracy (Figure 2).

Nevertheless, point-of-care medical 3d printing is not limited to anatomical models, but there are innovative personalized surgical (cutting) guides that streamline surgical procedures. Surgeons can virtually design a personalized surgical plan by thoroughly reviewing the patient's complex anatomical structures, thus reducing surgical risk, increasing efficiency, and improving patient satisfaction. For instance, personalized surgical guides are invaluable in craniomaxillofacial (CMF) surgeries, such as in tumor or orthognathic procedures, as they guide surgeons to make precise resections, place implants in their optimal positions, and achieve the best outcomes [4,5].

Moreover, the University Hospital Basel is at the forefront of developing 3D-printed implants for medical applications. These 3D-printed custom-made solutions are revolutionizing personalized medicine, from high-performance polymeric materials to biodegradable bone scaffolds [6,7].

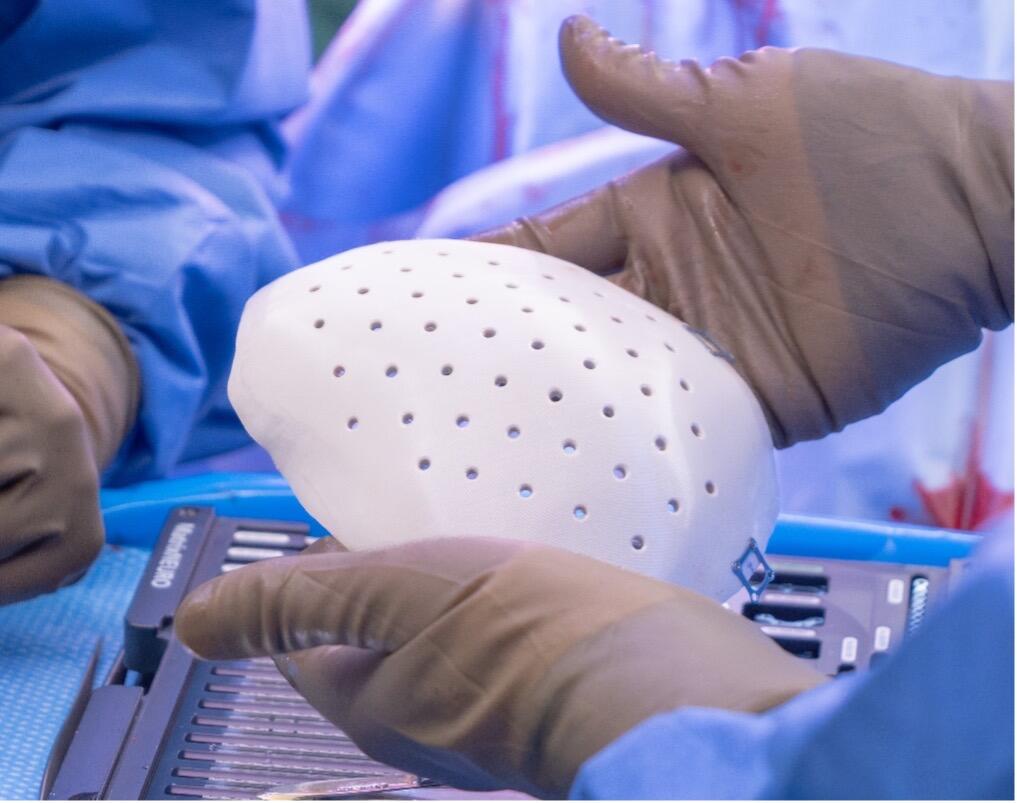

In a recently operated case, a patient suffering from a severe cranial deformity underwent a reconstructive surgical procedure at the University Hospital Basel. Utilizing the cutting-edge capabilities of point-of-care medical 3D printing, a 3D-printed patient-specific Polyetheretherketone (PEEK) cranial implant was designed and fabricated in-house to fit the contours of the patient's skull precisely. This 3D-printed PEEK implant addressed the aesthetic concerns caused by the deformity and played a pivotal role in restoring the patient's neurological functions (Figure 3).

Integrating in-house fabrication of personalized 3D-printed implants is a significant leap forward in the medical field. Unlike prefabricated implants, which may not always be a great fit, these 3D-printed patient-specific implants are a perfect solution that perfectly matches the patient's anatomy. This improves the aesthetic result, reduces the chance of adverse events, and brings about a better, long-lasting outcome. Furthermore, the production and delivery of personalized 3D-printed PEEK cranial implants indicate a fundamental change in the healthcare approach. By employing point-of-care medical 3D printing, healthcare professionals can now provide patients with customized treatment alternatives that best fit their individual requirements [8]. These examples demonstrate that point-of-care medical 3D printing can change the standard of care and surgery outcomes (Video).

One of the most significant advantages of point-of-care 3D printing is its ability to drastically reduce the turnaround time for producing medical devices. Instead of relying on an external company that will deliver custom-made implants after several weeks or months have passed, hospitals can print these medical devices in-house based on their immediate needs, and many times, the whole fabrication process will take no more than a couple of days. Thus, an in-house digital fabrication approach not only streamlines the treatment process but also minimizes the risk of complications and improves patient outcomes [9].

Additionally, medical 3D printing technology can be used in various specialties since it is versatile. From craniomaxillofacial surgery to orthopedics, dentistry to neurosurgery, and more, the scope of rapidly customized point-of-care medical 3D printing is almost boundless. Whether it is producing anatomical models for advanced surgical planning, developing patient-specific tools for complex treatments, or fabricating biocompatible customized implants, this technology allows medical professionals to personalize the healthcare system in an unprecedented manner [10].

Nevertheless, the advent of point-of-care medical 3D printing also brings a series of questions, just like any other disruptive innovation. Establishing regulatory barriers, quality assurance criteria, and cost-effectiveness are crucial issues that need to be addressed if the spread of this technology is to be promoted and brought into the mainstream healthcare practice [11].

The challenges encountered during the point-of-care medical 3D printing should not be seen as a downside of this technology but rather as a new area of learning and development. Innovation is the essence of progress, and 3D printing at the point-of-care represents the dynamism and dynamics of the technology in the healthcare field. As technology continues to evolve and become more accessible, we can expect even more significant advancements in personalized medicine, paving the way for a future where every patient receives tailored treatment that optimally addresses their individual health needs, drives efficiency in healthcare delivery, and saves lives.

Reviewed by

Florian Früh, Editorial Board

- Thieringer, F.M., Honigmann, P., Sharma, N. (2022). Medical Additive Manufacturing in Surgery: Translating Innovation to the Point of Care. In: Ehsani, S., Glauner, P., Plugmann, P., Thieringer, F.M. (eds) The Future Circle of Healthcare. Future of Business and Finance. Springer, Cham.

- Msallem B, Sharma N, Cao S, Halbeisen FS, Zeilhofer HF, Thieringer FM. Evaluation of the Dimensional Accuracy of 3D-Printed Anatomical Mandibular Models Using FFF, SLA, SLS, MJ, and BJ Printing Technology. J Clin Med. 2020;9(3):817.

- Ye Z, Dun A, Jiang H, Nie C, Zhao S, Wang T, Zhai J. The role of 3D printed models in the teaching of human anatomy: a systematic review and meta-analysis. BMC Med Educ. 2020;20(1):335.

- Slavin BV, Ehlen QT, Costello JP 2nd, Nayak VV, Bonfante EA, Benalcázar Jalkh EB, Runyan CM, Witek L, Coelho PG. 3D Printing Applications for Craniomaxillofacial Reconstruction: A Sweeping Review. ACS Biomater Sci Eng. 2023;9(12):6586-6609.

- Wegmüller L, Halbeisen F, Sharma N, Kühl S, Thieringer FM. Consumer vs. High-End 3D Printers for Guided Implant Surgery-An In Vitro Accuracy Assessment Study of Different 3D Printing Technologies. J Clin Med. 2021;10(21):4894.

- Basgul C, Spece H, Sharma N, Thieringer FM, Kurtz SM. Structure, properties, and bioactivity of 3D printed PAEKs for implant applications: A systematic review. J Biomed Mater Res B Appl Biomater. 2021;109(11):1924-1941.

- Chi M, Li N, Cui J, Karlin S, Rohr N, Sharma N, Thieringer FM. Biomimetic, mussel-inspired surface modification of 3D-printed biodegradable polylactic acid scaffolds with nano-hydroxyapatite for bone tissue engineering. Front Bioeng Biotechnol. 2022;10:989729.

- Sharma N, Aghlmandi S, Dalcanale F, Seiler D, Zeilhofer HF, Honigmann P, Thieringer FM. Quantitative Assessment of Point-of-Care 3D-Printed Patient-Specific Polyetheretherketone (PEEK) Cranial Implants. Int J Mol Sci. 2021;22(16):8521.

- Ostaș D, Almășan O, Ileșan RR, Andrei V, Thieringer FM, Hedeșiu M, Rotar H. Point-of-Care Virtual Surgical Planning and 3D Printing in Oral and Cranio-Maxillofacial Surgery: A Narrative Review. J Clin Med. 2022;11(22):6625.

- Bastawrous S, Wu L, Liacouras PC, Levin DB, Ahmed MT, Strzelecki B, Amendola MF, Lee JT, Coburn J, Ripley B. Establishing 3D Printing at the Point of Care: Basic Principles and Tools for Success. Radiographics. 2022;42(2):451-468.

- Hellman S, Frisch P, Platzman A, Booth P. 3D Printing in a hospital: Centralized clinical implementation and applications for comprehensive care. Digit Health. 2023;9:20552076231221899.